What is the best vacuum for tile floors? A sincere top 5 overview. Tile flooring can look extremely dirty if its not cleaned on a regular basis. The cleaning frequency often depends upon the color of tiles and grout.

Also tiles clearly tend to show up dirt more than rugs, carpets or other types of floor covering and it’s for this reason tile floors need to be cleaned more often. No matter if we’re talking about mosaic, natural stone, marble, ceramic, quarry (unglazed ceramic), porcelain or glass, tiles tend to accumulate mud, dust and debris fairly easy, but one of their main advantages is that they can also be cleaned easier, especially with the units I’m going to present in the following minutes. If you’re in a hurry, check out my top of vacuum cleaners, mops and scrubbers (arranged in no particular order): Most experts suggest that ceramic floors should be cleaned everyday using soap water and scrubs, but is there any solution for allergens and dirt particles?

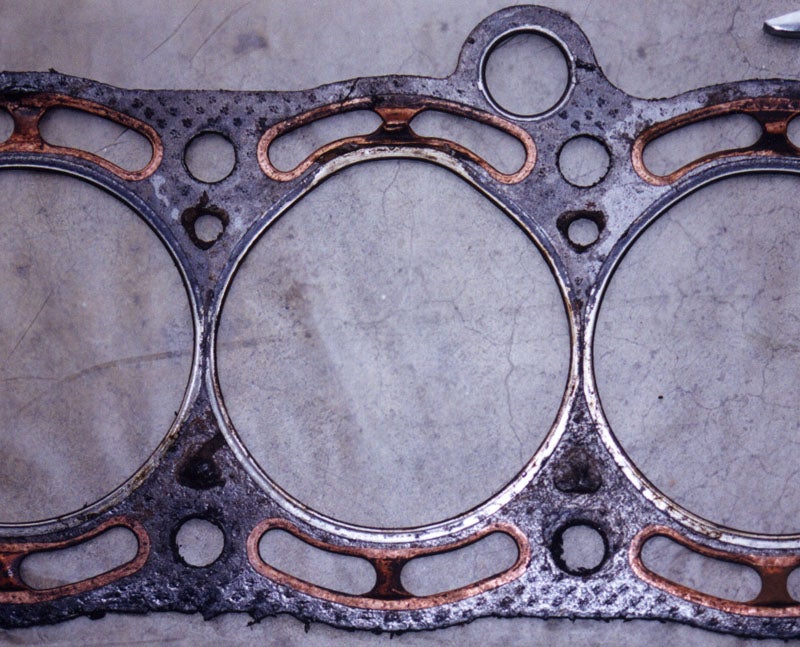

- Some of the More Popular Gen I Cast Iron GM Cylinder Heads #3767754 – Manufactured from 1959-1961 on 283 Cubic Inch engines. Called the “Power Pack” cylinder.

- Ford FE Engine Intake Manifolds: The Ultimate Guide- Build Max Performance for the 332, 352, 361, 390, 406, 410, 427, and 428 Engines and How to Stroke Your Engine.

- View and Download GMC G service manual online. G Trucks pdf manual download.

- How to Upgrade Chassis in Your Chevelle - Step by Step - Covers the 64, 65, 66, 67, 68, 69, 70, 71, 72 Chevelles.

- This is a glossary of technical terms, jargon, diver slang and acronyms used in underwater diving. The definitions listed are in the context of underwater diving.

- F8J BuNo 150904 at the Kalamazoo (MI) Air History Museum. Photo Courtesy Charlie Dosch (VF-11) Updated 27 Dec. 1997 THE MUSEUM: The museum is chartered as a non.

Of course there is! You can either scrub them off, or you could vacuum them. This is where vacuum cleaners play a vital role. When you use a powerful vacuum to remove surface dirt, you also get to the bottom of the debris that has been collecting on your tile floor. Thus, you can sit back and relax knowing that your tiled floors are being properly cleaned and that there won’t be any build up over time.

The Alfa Romeo Montreal Website. This is an independent website, maintained by Bruce Taylor, Geneva, Switzerland, and last updated 18 July 2017. Keep fingers away from the ejector slot when loading or testing. Inspect the grinding disc for defects such as cracks. Lumber, Plywood, Millwork, and Wood. This page lists the summaries of all Airworthiness Directives (ADs) issued to all series of Boeing 737 since July 2007. The links take you to the full AD.

Choosing the best vacuum cleaner for tiles. There are different types of cleaning machines for tiled floors available on the market today. Let’s have a close look at some important aspects that will help you in making an informed decision. Quarry vs. However, unglazed tiles attract dirt and need higher maintenance.

For quarry tiles, you’ll have to invest in a powerful vacuum cleaner that comes available with a wet brush or mop as an accessory, because these type of floors require lot of damp mopping. Cleaning grout – You can clean grout, ovens, fridges and many many other things with a mix of baking soda and tap water. Grout absorbs grease and gets stained easily.

After cleaning it, you can apply a silicone- based sealer that ensures that future accidents won’t leave permanent stains. Steaming – Several cleaning machines offer the possibility to vac and steam in the same time.

This is particularly needed in the case of tiles, since this type of flooring is resistant to high temperatures and can be easily sanitized. Controlling the brushroll – Since tile floors may be accounted as bare floors, you will definitely need an upright which offers the possibility to turn the head brushroll off, so all dirt will be sucked inside the machine, instead of being spread off behind and around the machine. Filtration options – The perfect vacuum for tiles should have a good filtration system, since tile flooring particularly accumulates more electrostatic dust. I’ve already covered in this guide most of the filtration options, be sure to check it out. Types of vacuum cleaners – The best vacuum for tile floors is either a canister or an upright model.

You should be very careful in choosing its attachments, as some can even scratch tiles. One important thing to keep in mind: when buying a vacuum for tile floors, you should pick one that is very maneuverable. This type of flooring is a bit slippery, thus the vacuum cleaner you choose should have strong rubberized wheels, especially if it’s an upright model. Cordless models are preferred (or at least lightweight models).

Autonomy – Speaking of cordless vacuum cleaners, you should consider buying only those with good batteries. Higher voltages indicate that the product has more suction power. Choose vacuum cleaners with batteries that deliver 1. Volts or more, and that could last for 3.

Another thing you should keep in mind when shopping for a cordless is the charging time. Anything more an 8h is IMO unacceptable. Top vacuum cleaners, scrubbers and mops for Ceramic Floors.

Let’s have a close look at the best unit, that can easily clean your tiles effectively and ensure they’re always sparkling clean: Shark Rocket Powerhead. The brand new Rocket Powerhead is a lightweight vacuum that ensures powerful cleanup of your tile floors. With the latest brushroll technology, you’ll get your tiles cleaned in no time. You can also manually switch between brushrolls, pop up the dust bin in seconds and control the unit using the ergonomic handle and the digital controls located on it. The suction power is impressive. No dust or debris escapes its airflow. Key Characteristics of the Shark Rocket Powerhead: Lightweight vacuum with superior suction, 2 types of brushrolls and an ergonomic handle to easily clean both dust and pet hair.

Provides a low gravity center, so it’s perfect for people with back problems. Economical 6. 00. W motor and LED lights. Unique swivel steering. Long 5 year warranty. Read my complete assessment or more reviews of this product. Dyson V6 Absolute/Fluffy.

The V6 is another great unit for vacuuming tile floors. If you have even tiles, the Fluffy version is all you need, else you may want to consider the Absolute model which also comes with a motorized brushroll which also works very well on low pile carpets. The Fluffy nozzle is designed to pick up lots of stuff, from cheerios to pet dander.

The suction of this cordless is more than you need, but there’s one catch: the batteries last around 2. If you can work with this, then this unit is perfect for you. Thanks to its smart design, you can maneuver it with ease on or above the floor.

Besides standard accessories (such as a crevice tool or a dust brush), the kit also includes a wall- charging dock which is a perfect storage solution. Key Characteristics of the Dyson V6 Absolute: Miele Classic C1 Olympus. Miele C1 Olympus is not only great for tile floors, but also works on hardwood flooring and low pile carpets. This entry level unit from Miele has a powerful suction and a very good filtration system, which ensures a quality air flow.

Although it’s a canister, the hose handle is comfortable and ergonomically correct. The motor of the vacuum is very efficient and is designed to run on a low amount of power. One good feature is its high capacity dust bag. It is completely sealed and easy to dispose. Due to its light weight (about 1.

You can move around, cleaning different areas of your house, as it has a 2. The sound level is also very low, which is a big plus IMO. Key Characteristics of the Miele Olympus: Excellent filtration system. Large 1. 2 gallon bags. Great suction power, perfect for tiles and other even/uneven bare floors.

In fact, it looks like it is designed specifically for tile floors, low to medium pile carpets, and area rugs. Read what other are saying about this vacuum cleaner. Bissell Symphony All- in- One Vacuum and Steam Mop (1.

With this product, you can ensure a complete tile floor clean in one easy step. The new Bissell Symphony is an innovative vacuum, as well as steam cleaner. You can completely clean and sanitize bare floors without using bucket and mop or any harsh chemicals. The Symphony uses tap water to produce a powerful steam. Its Easy Touch Digital controls allow you to seamlessly switch between its multiple functions while cleaning, and you can vacuum and steam at the same time or even separately to match the right clean for the right situation. That means you wont’ have to spend hours in sweeping your tiled floor and then mop it separately! In fact, Bissell terms it as a “One Step Cleaning” – using just one device.

You’ll be able to clean your floors, in just one pass without any need to broom or mop. Plus, its unique steam feature is lot easier than having to use a mop and bucket.

When you’re done, you can easily pack it off using the Quick- Release Mop Pad Tray and an adjustable handle which makes storing a bliss. The results: a barefoot- ready, fresh clean floor that you and your family will love.

The Bissell Symphony comes with two machine- washable and reusable pads, one for scrubbing and one for cleaning. According to manufacturer’s manual, this vacuum cleaner is safe for all types of hard surfaces, including tile floors. You can also use it on vinyl floors without worrying about any damage. If you have other types of flooring, it’s better to test in on a small area before proceeding with cleaning your entire floor. Key Characteristics of Bissell Symphony: You can easily sanitize with steam, using just water for getting rid of up to 9. It saves lot of time by vacuuming and then steaming tile flooring at the same time.

It has easy- to- use digital controls and an unique 5 way adjustable handle. Its Quick Release Pad Tray is easy to handle, and the package comes with 4 mop pads included. It provides speedy cleaning and mopping and has user friendly design. Unique Dry Tank Technology will keep your tank dry while you’re steaming.

Check out my Bissell Symphony complete review, or find out what other buyers are saying about this vacuum cleaner. Hoover Floormate Deluxe. Hoover Floormate is a classic scrubber. People have been using Floormates for years, and I’ve talk with dozens of satisfied customers.

Hoover recently revamped its line with new models, even a cordless version. The Floormate Deluxe is the newer brother of the Hoover Spin. Scrub. It doesn’t vacuum any more, but the scrubbing capabilities have improved. The dirty water is now completely separated from the clean water, in 2 different reservoirs, each with a 4. The product is relatively light- weighted at 1. There are 2 cleaning modes which you can use to clean your tiles: Wash and Dry.

Key Characteristics of Hoover Floormate Deluxe: Comes with proprietary counter- rotating brushes. Wash and Dry. Comes with a 1.

The handle folds for easier storage. It’s relatively cheap. Shark Sonic Duo Carpet and Hard Floor Cleaner (ZZ5. The Shark Sonic Duo is a power packed machine that promises you a quick and easy way to remove all types of stuck dirt that holds odors and allergens from area rugs, carpets and tile floors.

Ramp Head Merlin. The Rolls- Royce Merlin Aero Engine. Early Development 1.

The Ramp Head Merlinby J. Wells. Trentham, Victoria, Australia. The first part of this article, . Spring of 2. 00. 6.

This version is the 4th Edition, which was released in February 2. The Genesis of the Merlin. In 1. 93. 2, Frederick Henry Royce (F. H. R.), knight of the realm and autocratic head of Rolls- Royce Ltd, decided the time was apposite to design a new, high- power, military aero- engine. At that point in time, F. H. R., then aged 6. As far as a new engine was concerned, Royce had a number of options available to him, including: 1) development of the Kestrel,2) development of the Buzzard,3) detuning of the .

The creation of the first monoblock aero- engines of Rolls- Royce had been prompted by the appearance of the Curtiss D- 1. R- R were sent a complete example of the D- 1. Eng. 2. 52, the very last of the B- models) by the Air Ministry who suggested that F. H. R. In no time at all they found themselves up to their necks with problems of overheating and piston seizure, which they solved by switching to a wet liner design. But the damage had been done because in the dry liner scheme, the cylinder blocks were secured to the crankcase by four rows of seven bolts, i. In the wet liner design, only the liners connected the blocks to the crankcase.

Four bolts per cylinder were insufficient and in Rubbra’s words, . These would sometimes lead to a cylinder becoming partially filled with water on standing resulting in a failed con- rod when starting up.

From Kestrel experience, R- R had learned that each cylinder needed six cylinder head studs. This move terminated the leaking of the top joints in both the Buzzard and the highly modified . The PV- 1. 2 was to have two features which would distinguish it from previous designs. First, to ensure there would be no repetition of the internal coolant leaks, separate cylinder heads would be used so that a close eye could be kept on the liner top joint. According to Rudd. The heads, cylinder blocks and crankcase would be assembled in close contact with each other thus giving mutual support. A third, minor difference, was that the capacity would be between that of the Kestrel and the Buzzard.

Thus the PV- 1. 2 was born — its construction consisted of three major components; the upper crankcase plus the cylinder blocks and the two cylinder heads. This kind of constrction is the simplest and strongest way of making a V- shaped engine. Millions of V- 6 and V- 8 aout engines attest to that.

All other components including crankshaft, pistons, and valve mechanism were carried over from the Kestrel/Buzzard. Inverted layout, evaporative cooling and herringbone reduction gears were toyed with but quickly discarded. Two PV- 1. 2s were built with factory numbers were 1 and 3 (odd numbers only for right- hand tractor engines) and, initially, the construction was funded by by Rolls- Royce Ltd. Paradoxically, of the 1. Merlin engines that were subsequently manufactured, only the first two were actually made as the Great Man intended. Later the government paid for the engines and the usual . To help him with his deliberations and to facilitate liaison with the main works, an engineer named Albert George Elliott was hired.

By all accounts an affable fellow, Elliott got on well with F. H. R. Elliott felt that the key to avoiding detonation and ensuring clean burning was turbulence of the mixture — not just turbulence due to the gases rushing past the inlet valves but extreme and violent swirling generated by the piston moving the mixture into the combustion chamber during the compression stroke. To make this happen, Elliott postulated the use of cube- shaped combustion chambers (Figs. The sides of these chambers, when assembled on top of the cylinders formed horizontal barrier walls that the mixture had to flow around during the upward movement of the piston to, . To make this distinction clear he said, . Whatever Royce thought of the theories there is not the slightest indication that he intended to apply them to the PV- 1. Kestrel- type cylinder heads.

Shortly before Royce’s death in 1. Elliott was transferred from the coast to Derby and given the influential post of Chief Engineer. The demise of Royce presented Elliott with a golden opportunity to apply his ideas on cylinder head construction and thus stamp his mark on Rolls- Royce engines. It would seem that he wasted no time in espousing his theories to his fellow Derby engineers because even before the end of 1.

R- R engineer James Denning Pearson had filed a patent . Clearly, it is the push- rod version of the ramp head in two- valve form, probably intended for a road vehicle. Pearson justifies the canting of the inlet valves from the vertical to the 4. Download Magi The Kingdom Of Magic Episode 12 Sub Indo Mp4 Player.

This invention has for its primary object to avoid such interference. The inlet valve is set at an angle of 4. An Extraordinary Decision.

An indication of Elliott’s determination to apply the ramp- head to all Rolls- Royce engines is given by noting that less than a month, after Pearson’s application for a two- valve ramp- head design, Elliott and Pearson filed a patent for a four- valve per cylinder version (Fig 1. This announcement would have been greeted with astonishment, amazement and probably, dismay by the engineers involved. They already had major problems to contend with and the introduction of an untried, untested modification to a brand new engine had the potential to add significantly to their woes. The logical step to take in this situation would have been to carry out a parallel course of development using at least one engine with standard- type cylinder heads. Perhaps it was an indication of Elliott; s obsession with the ramp- head design that this did not occur. The flat- head combustion chamber/valve arrangement had been tried proven by way of 4,7.

Kestrels, 1. 00 Buzzards and 2. It was sturdy, reliable, easy to maintain, inspect and service. In a new engine it was one of the known quantities and to change it during the early stages of the Merlin’s development was an invitation to disaster. However, Elliott got his way and two Merlins with ramp heads were built in 1. They were designated Merlin B and the Air Ministry numbers given to them were A1. A1. 11,1. 38. The first run of a Merlin B was February 2.

The ramp heads proved to be extremely troublesome as Rubbra points out,1. The power output was inferior to the flat- head design. The detonation characteristics were worse than with normal heads. There was burning of the exhaust port walls. There was wear and break- up of the rocker arm pads. At R- R, experimentation and engine testing was part of the company from the time it started. In any book on R- R motor cars, there are usually as many photos of prototypes on test as there are of production vehicles!

Ernest Hives (at the age of 3. Experimental Dept. For instance, the Single- Cylinder Beds were used to trial con- rods, pistons, bearings, valves, cams and liners, etc., and superchargers were developed and calibrated on their own test rigs.

The cylinder was the same size as one of the 'R' engine ones but it was much cheaper to develop the cylinder this way than running a complete engine. The object was to extract as much power as possible from the cylinder by improving valve cooling, spark plugs, ignition timing and so on. We developed it to give 2. BHP and it made a most frightful din! Extensive normal running and more importantly, over- load testing would have certainly revealed the subsequent whole- engine problems. A more likely explanation is that the unsatisfactory results were obtained but they were rationalized or even dismissed by Elliott (to whom such results would have come directly) whose faith in his invention was so blind that he was sure the problems could have been solved with a bit of development on complete 1. Clearly, he was operating on the principle often followed in the performing arts arena, .

As pointed out above, one of his first decisions as Chief Engineer was to substitute (not supplement) his ramp- head design for the usual arrangement. Ergo, he had no .

This is hard to understand because all through the aero- engine literature, mention of Rolls- Royce expertise with metal alloys invariably occurs. Accounts of Royce’s particular interest in the subject; of the establishment of a company research unit as early as 1. R- R alloys; of the importance of new alloys in keeping the .

Was the PV- 1. 2 design ahead of its time? Not a bit of it! One only has to look at the situation in Germany in the early 1. Daimler- Benz and Junkers were also preparing to manufacture high- powered, liquid- cooled, mono- block engines.

At Junkers, the Ju 2. R- R PV- 1. 2 — same one- piece upper crankcase/cylinder block casting; same separate cylinder heads; same unstressed wet liners, etc.

Even the valve gear with its single overhead camshaft (per bank) acting on cross- over lever tappets was identical to the R- R mechanism. In the context of this article, the Ju 2. The point being that Junkers managed to manufacture 6. The proposed remedy to the cracking was to separate the cylinder blocks from the crankcase and so the two PV- 1. Merlin Bs had the cylinder blocks unceremoniously sliced off the crankcases. Appropriate threaded holes were then drilled into the decapitated crankcases and new cylinder blocks were bolted on. This seemed to have help the cracking but in contrast, there were no solutions to the ramp- head problems.

Rubbra claims, . Elliott comments, . In their words, . According to this invention therefore an, ignition plug is located between the inlet valves. It also contradicts Rubbra's glowing assessment of the Goshawk B whose cylinder head was characterized by having all the spark plugs on the outside of the cylinder banks, much like the Mercedes DB 6.

New Posts

- Serial Number For Adobe Fireworks Cs3 Review

- Microsoft Office Training Sacramento Ca Real Estate

- Free Adobe Flash Player For Live Streaming

- Hack Pack 33 Hacking Tools Pack 2011 Ez Go Golf

- Change Software Language Sony Ericsson Xperia X2 Pictures

- Command Option Key On Windows Keyboard Lock

- Complete Windows Hacking Validation Tools Demons And Wizards